OVERVIEW

Companies depend on DeviceDev Consulting, Inc. to turn their dreams into actual working products. We work with our customers to take a project from a concept, through brainstorming, prototyping, engineering, and all the way to production.

We are lean and provide "budget fit" solutions with a high standard of quality. Our first hour of consultation is free.

LOCAL AND OUTSOURCING SOLUTION SERVICES

- Competitive Audit

- Concept Development

- Concept Sketching:

- Color, materials, and finish

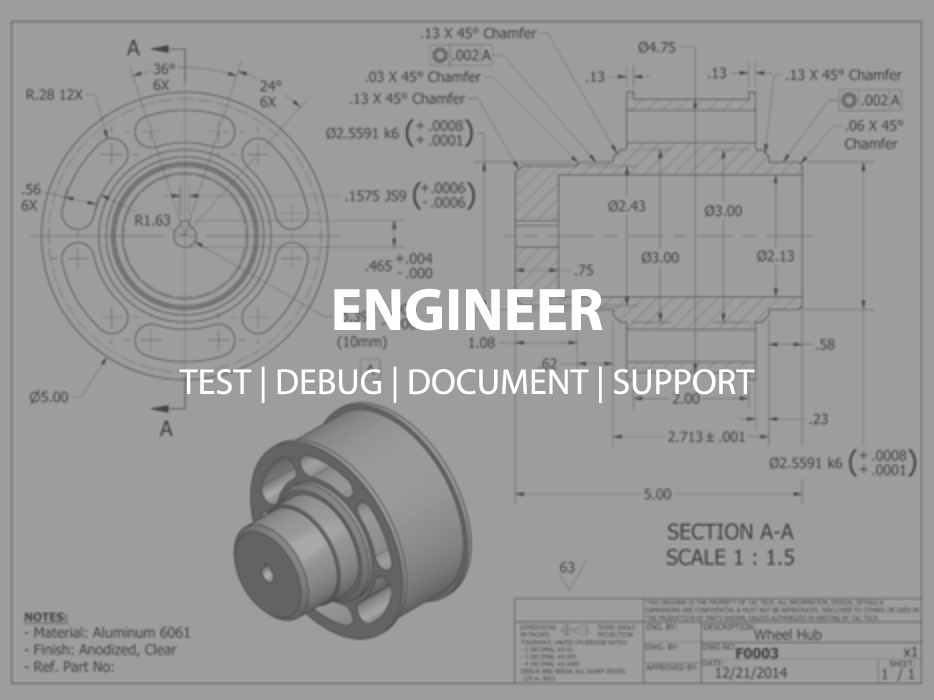

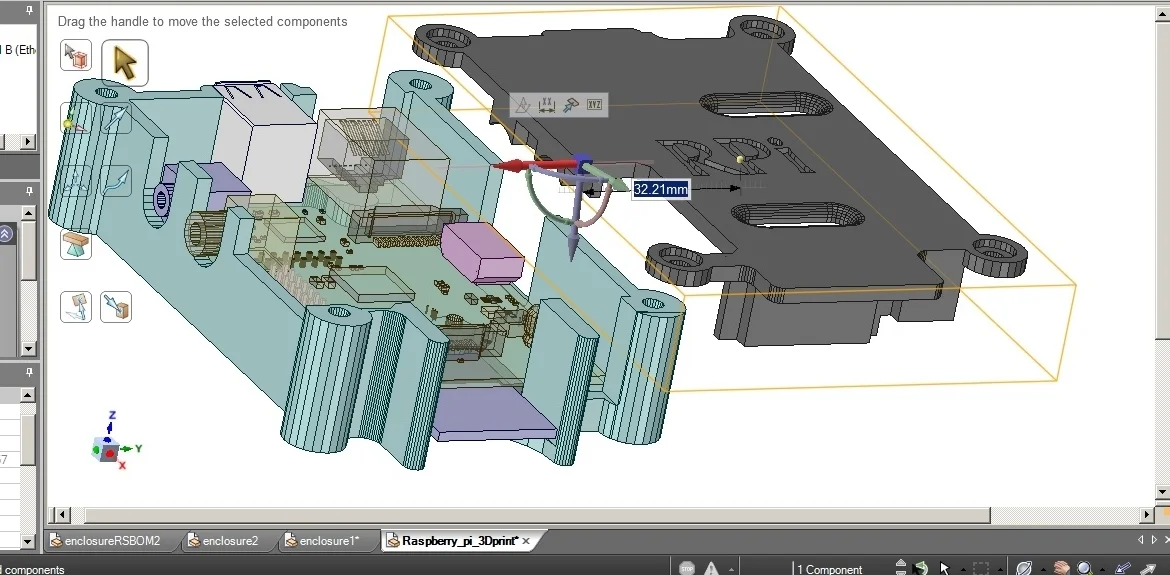

- CAD Modeling

- Surfacing and Parametric modeling via SolidWorks

- Engineering design for manufacturing and assembly

- Electrical component planning and integration

- Design validation/ optimization

- Testing and quality standards

- Engineering drawings and product documentation

- Pre-production, fabrication, and manufacturing support

- Look like form modeling/mock-ups

- Proof of concept: function, method or mechanism

- Rapidly prototype via 3d printing & CNC machining

- Pre-production prototypes

OUTSOURCING

- Plastic injection molding design and tool building

- Electronics, assembly, testing, sourcing and more

- Quoting and sourcing

- Part production and fulfillment

ISO 9001:2008 CERTIFICATE

Product design, mechanical engineering, and mass production services provided through us from now meet the standards of ISO 9001:2008 quality management system.